Sewer Boring

Force Main Sewer - Sewer Boring Contractors

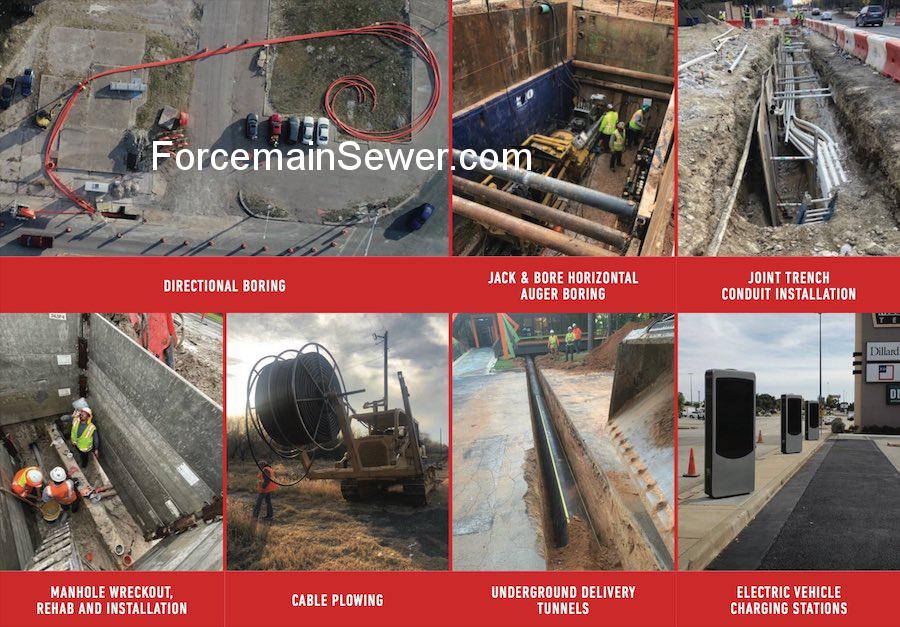

Sewer boring is a trenchless method used in infrastructure construction to install or replace underground pipelines and utilities, including sewer systems. This technique is often employed in horizontal auger boring, jack and bore, and other related methods to minimize surface disruption. Below is an explanation of how sewer boring ties into various components:

Force Main Sewer - Sewer Boring Companies

1. Horizontal Auger Boring

- Use: Horizontal auger boring involves a rotating cutting head attached to an auger drill that removes soil while simultaneously installing a casing pipe.

- Application: This method is used for sewer installations under existing infrastructure, such as roads and railways, ensuring accuracy and minimal surface disturbance.

2. Jack and Bore

- Use: Jack and bore is a trenchless technique where a casing pipe is pushed (jacked) through the ground while soil is removed by an auger.

- Application: Commonly used for installing sewer pipes on-line and on-grade to maintain alignment and slope, essential for gravity-fed systems.

3. On-Line and On-Grade

- On-Line: Refers to maintaining the proper horizontal alignment of the sewer pipe.

- On-Grade: Ensures the pipe is installed at the correct slope (% fall) to allow gravity to move sewage efficiently. Laser-guided boring systems are often used to ensure precision.

4. Force Main Sewer Lines

- Use: For sewer systems under pressure, force main pipes transport wastewater with the help of pumps.

- Application: Boring methods are utilized to lay force main pipes under roads, rivers, or other obstacles with minimal disruption.

5. Sanitary Sewer Systems

- Use: These systems transport wastewater from homes and businesses.

- Application: Boring allows for installation beneath urban areas without open trenches, preserving streets and sidewalks.

6. Gravity Sewer Systems

- Use: Relies on gravity to move wastewater through pipelines.

- Application: Precise boring ensures the pipe maintains a consistent slope (% fall), critical for gravity sewer operation.

7. % Fall

- Definition: The slope or gradient of the sewer pipe, expressed as a percentage, determines the flow efficiency.

- Application: Boring methods are ideal for achieving precise slopes, especially for gravity systems.

8. Manholes

- Use: Manholes provide access points for maintenance and inspection of sewer lines.

- Application: Sewer boring connects manholes by creating underground pathways for pipes.

9. Grinder Pumps

- Use: Grinder pumps are used in areas where gravity sewer systems are not feasible, grinding and pumping wastewater to higher elevations.

- Application: Force main pipes installed via boring are connected to grinder pump systems.

10. Roads

- Use: Sewer boring is commonly performed beneath roads to avoid open cuts and traffic disruption.

- Application: Techniques like jack and bore or horizontal auger boring are preferred for their minimal impact on existing roadways.

11. Municipal Applications

- Use: Municipalities rely on sewer boring to install or upgrade sewer infrastructure efficiently in urban and suburban areas.

- Application: The method supports large-scale projects while preserving public spaces and reducing environmental impact.

Force Main Sewer - Sewer Boring Near Me

Benefits of Sewer Boring

- Minimizes surface disruption.

- Maintains precise alignment and slope.

- Reduces construction time and costs.

- Protects existing infrastructure like roads and utilities.

- Ideal for urban environments where open trenching is impractical.

Sewer boring is an integral part of modern infrastructure development, especially in densely populated areas and for environmentally sensitive projects.